Tec-Alert Newsletter

EMERGENCY FIBER RESTORATION: Don't Get Caught Unprepared!

Introduction

IntroductionNo cable is invulnerable to catastrophic failures or damage. Yet, many times, OSP crews and service managers operate as if this were true. The ONLY way to mitigate the risk is to be prepared. Planning, preparation and training can go a long way toward minimizing downtime in the event of a failure. As we all know, downtime means higher costs and lost opportunity in the form of unhappy customers.

Faced with the reality that cables WILL be damaged, what can you do about it right now? The goal of any emergency restoration effort is to restore service as quickly as possible thus minimizing the impact on customers. In this article we will help you begin a basic plan or strategy to make this goal a reality for your fiber cabling plant.

Make a Plan

The first step in effectively addressing catastrophic failures is to have a planned response in place prior to any failure. This planning involves asking and answering a few key questions:

1. What equipment, training, etc. must be in place BEFORE a failure occurs?

2. How will we know that a failure has occurred?

3. What is our Emergency Response procedure? Steps involved, personnel responsible, etc.

4. Once a failure has been detected, who is trained, stocked and responsible for performing the restoration?

5. How do we assess the success of the restoration? Speed of restoration, completeness of restoration, cost of restoration.

Once answers to these key questions have been determined the next step is to ensure that the "Plan" is ready for execution when needed.

Have Supplies in Place

Personnel: To effect any fiber restoration, you will need to have trained personnel in place who know and understand your procedure and can perform the type of restoration required. These service experts may be your own on staff people or an outside contractor. Regardless, don't take training for granted. The worst case scenario is to attempt a restore and fail due to lack of training.

Supplies: The ideal Emergency Fiber Restoration Kit (EFRK) would contain every type and fiber count replacement cable used throughout your entire plant and all the necessary tools and equipment to install them.

This is usually impractical from a cost standpoint. The next best solution is to have ready at all times an EFRK with all the necessary tools, supplies, consumables and at least 300 feet of cable containing enough fibers to be used almost anywhere in the network.

NOTE: Also, make sure your splice enclosures can accept the required number of spliced fibers as well.

Click here to see our NEW Emergency Fiber Restoration Kit.

Several of these EFRKs should be deployed throughout your network either in specific POPs or in the crew vehicles of all restoration trained personnel. That way the crew or facility nearest the break can respond rapidly and competently without waiting for supplies.

When building or purchasing your EFRK, select components that are easy to use, and provide flexibility for different situations (e.g. buried or aerial deployment). Click here to see our NEW Emergency Fiber Restoration Kit.

Typical Emergency Fiber Restoration Kit Contents:

- Fiber Optic Splice Closures (2 or more).

- Splice Holding Trays for the spliced fibers.

- High Fiber Count Restoration Cable (At least 300ft).

- Enough mechanical splices or fusion splice protectors to splice all the fibers in the cable TWICE (Once at each end of the break).

- Consumables for cleaning the cable and fibers.

- Tools for prepping the cable sheath.

- Tools for stripping and prepping the fibers before splicing.

- Good Quality Fiber Optic Cleaver.

- Mechanical Splicing Kit or Fusion Splicer.

Other equipment that may also be required

- OTDR.

Understanding the Emergency Restoration Process

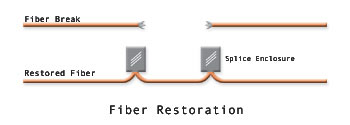

Scenario: A cable has been completely severed by a backhoe at a construction site. The cut is near the middle of a 5000 foot run and there are no splice points nearby.

Emergency Fiber Restoration Process

0. Prepping, cleaning and stripping the restoration cable can often be done in advance. This will save time once your crew arrives onsite.

1. Locate and access the cable break.

2. Remove at least 10m (32 ft) of cable on either side of the break. This helps ensure that the remaining cable is undamaged. Test the remaining lengths using an OTDR to verify they are undamaged.

3. Prep, clean, strip, and cleave the fibers. Here is where having the restoration cable prepared beforehand can save time.

4. Splice the fibers together and load each spliced fiber into the splice enclosure. Often mechanical splicing is preferred because of its simplicity and speed. This temporary restoration will restore critical service rapidly and the system can be taken down later for permanent fusion splicing repairs.

5. Perform the steps 1-4 on the other end of the damaged cable.

6. Check system alarms or test with an OTDR before completely sealing the closures.

7. Close and seal spice closures. Test complete system after final deployment of the cable to confirm successful fiber restoration.

Summary

As we have seen, the best way to prepare for an emergency is to plan

ahead! By having a plan, trained personnel and required equipment in

place before a break occurs, your next restoration can be smoother,

faster and a lot less costly!

Return to Top of Page Go back to Tec Alert

BUILD YOUR OWN TOOL KIT

Subscribe to our Tec-Alert Email Newsletter

Get tips & information for field service and MRO professionals.

* indicates required